2017: EMCO-120P lathe + BBB + MK + Modified Gmoccapy GUI

2015: C3000 machining center + BBB + MK + Qt based tablet remote GUI

2013: CNC-6040 router + PC + LCNC + Modified Gmoccapy GUI

Late 90s : Wolfcraft table based mill + PC + EMC/LCNC + Axis GUI

Author Archives: f1oat

CNC-6040 4 axis milling test

3D mesh captured with David Laser Scanner.

G-CODE file generated with trial version of Deskproto.

Milling job achieved on a www.cnc-shop.ch CNC-6040 router and harmonic drive based fourth axis.

EATC-120 toolchanger controller released

This is a DIY controller for the original Emco Turn 120/220 toolchanger.

Software, PCB and schematic are now available at: https://github.com/f1oat/EATC-120

Many thanks to Tom for the original Toolerator 3000 design that inspired EATC-120.

Emco Turn 120P door switch rebuild

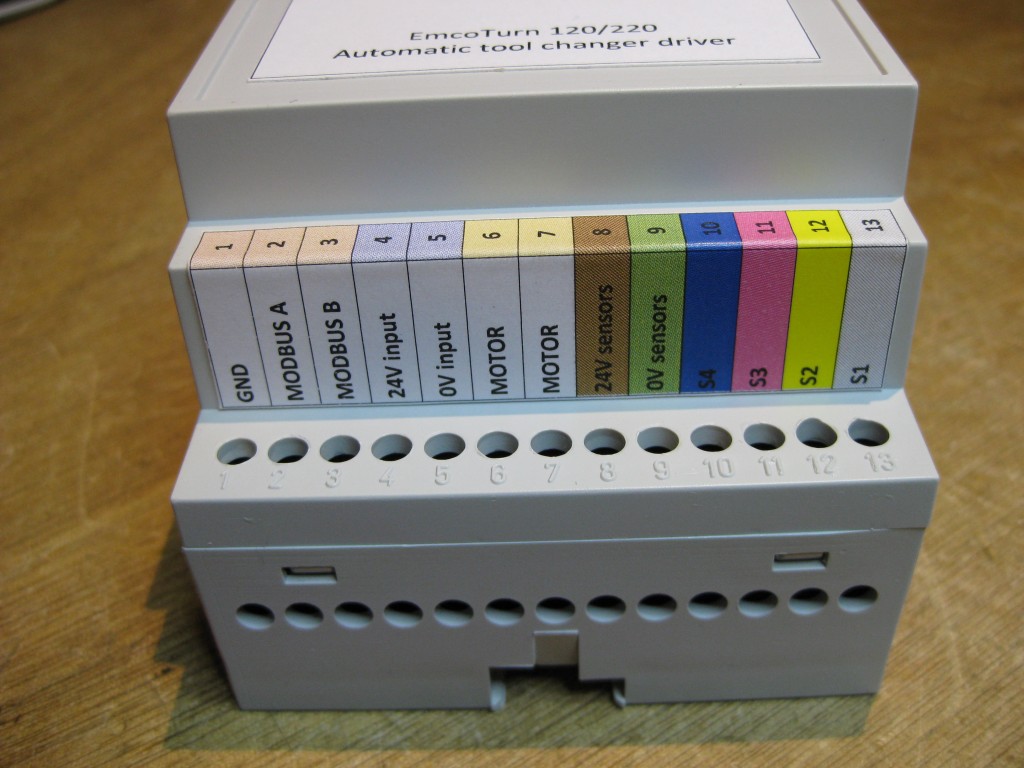

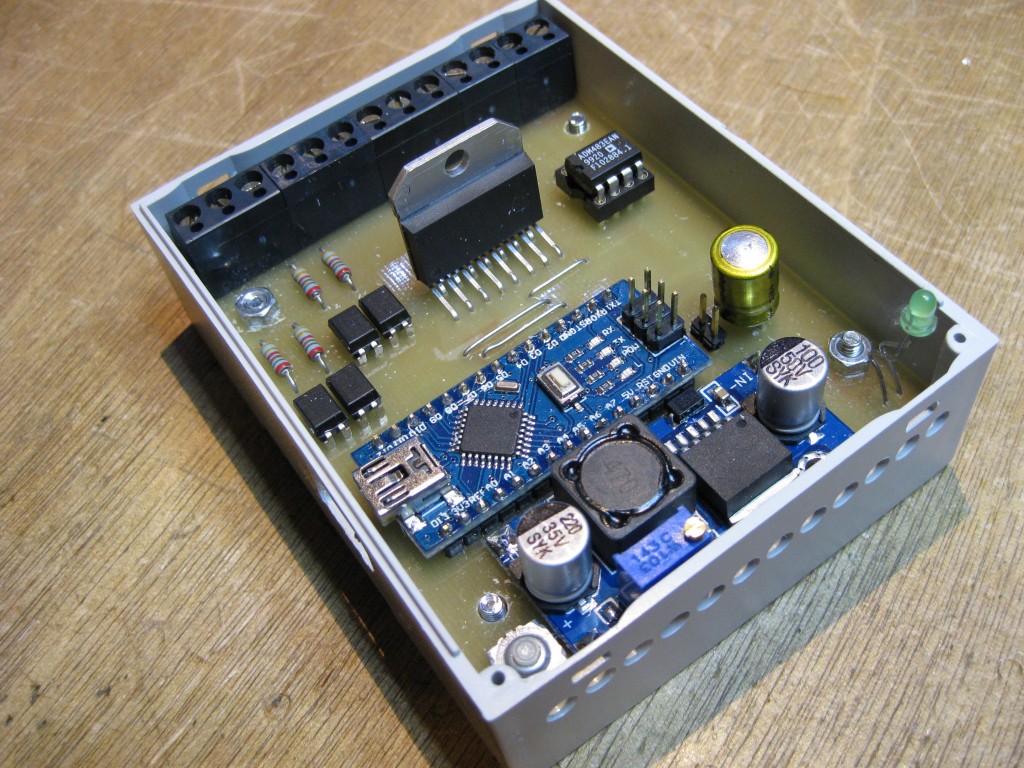

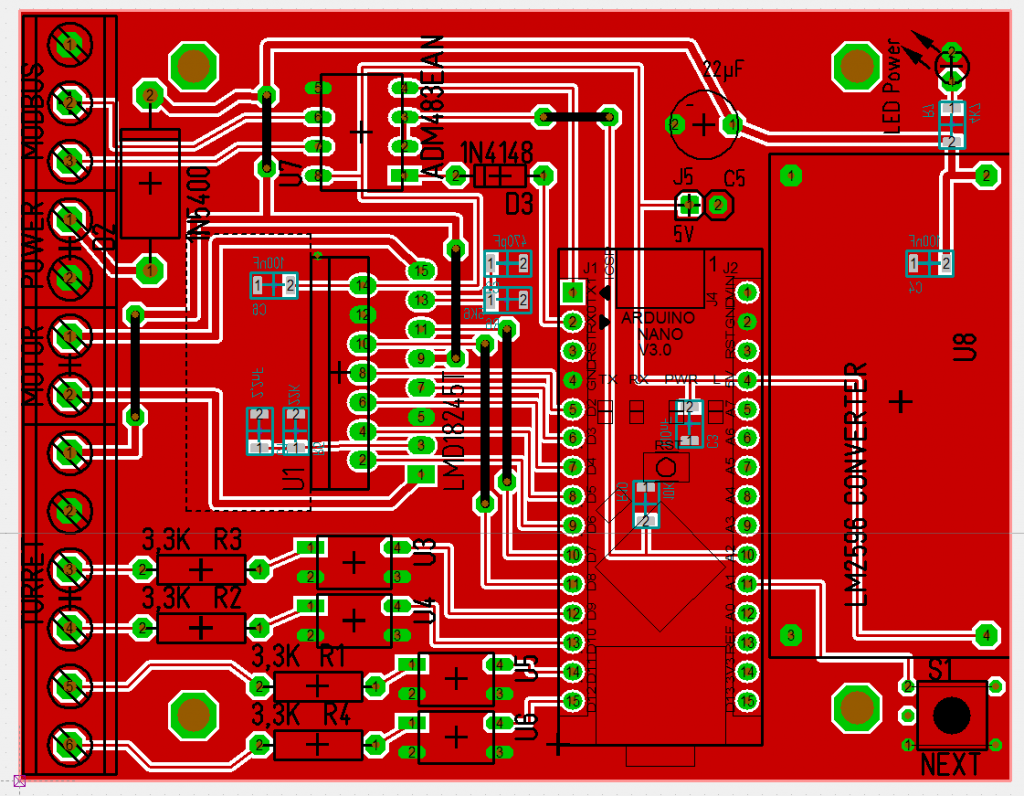

EATC-120 toolchanger driver

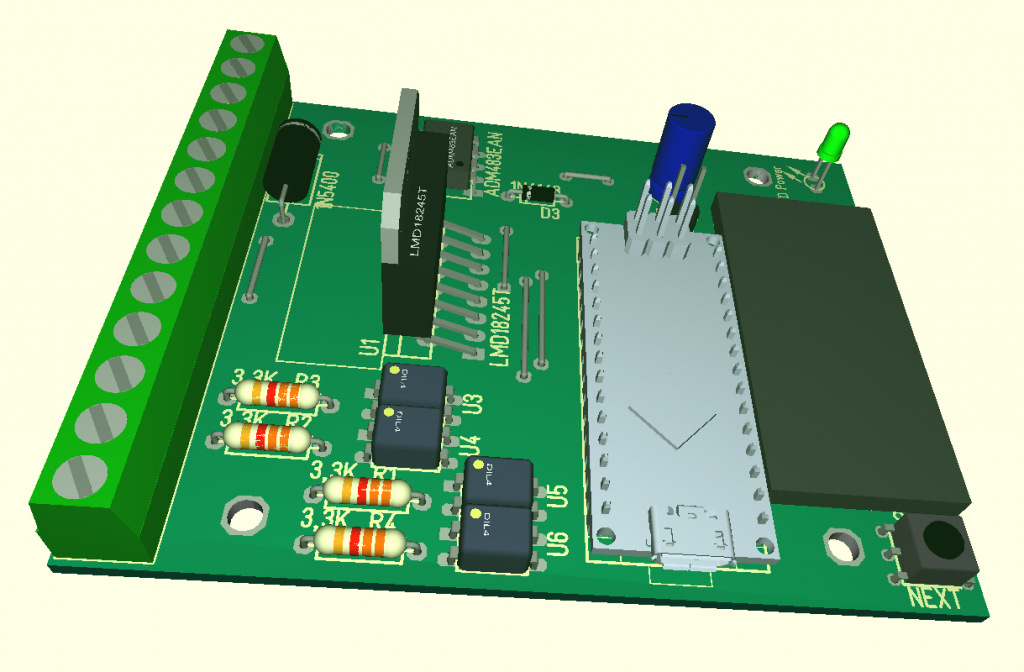

The EATC-120 module is almost finished !

This is a driver for the EmcoTurn 120/220 original 8 positions ATC.

This design is derived from the excellent Toolerator 3000 USB controlled driver.

EATC-120 is adding MODBUS capabilities for easy integration with an industrial environment.

Single 24V power supply with embedded 5V DC/DC converter.

The “brain” of the module is an Arduino Micro.

The motor is driven by an LMD18245T providing current control.

The lock status is automatically detected by measuring the peak current when the motor stalls.

Everything is reported in MODBUS registers.

Integration with Machinekit/LinuxCNC is easy thanks to “mb2hal” HAL component.

I have found a nice empty DIN rail enclosure and designed a special PCB to fit with it.

I need to finalize integration and test with my Emco lathe before publishing.

Stay tuned !

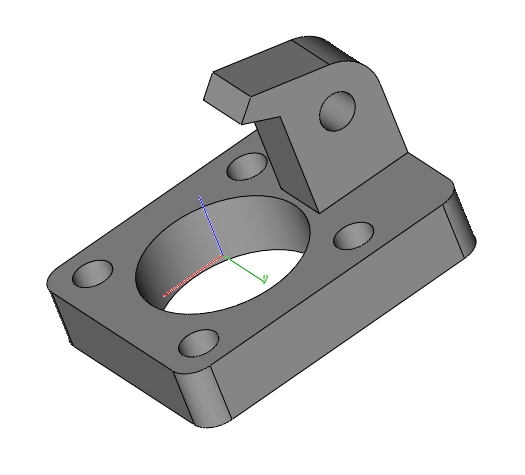

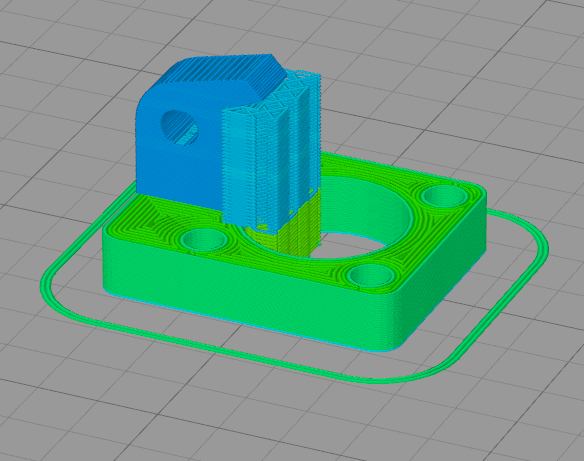

Control panel bracket

Motor drivers

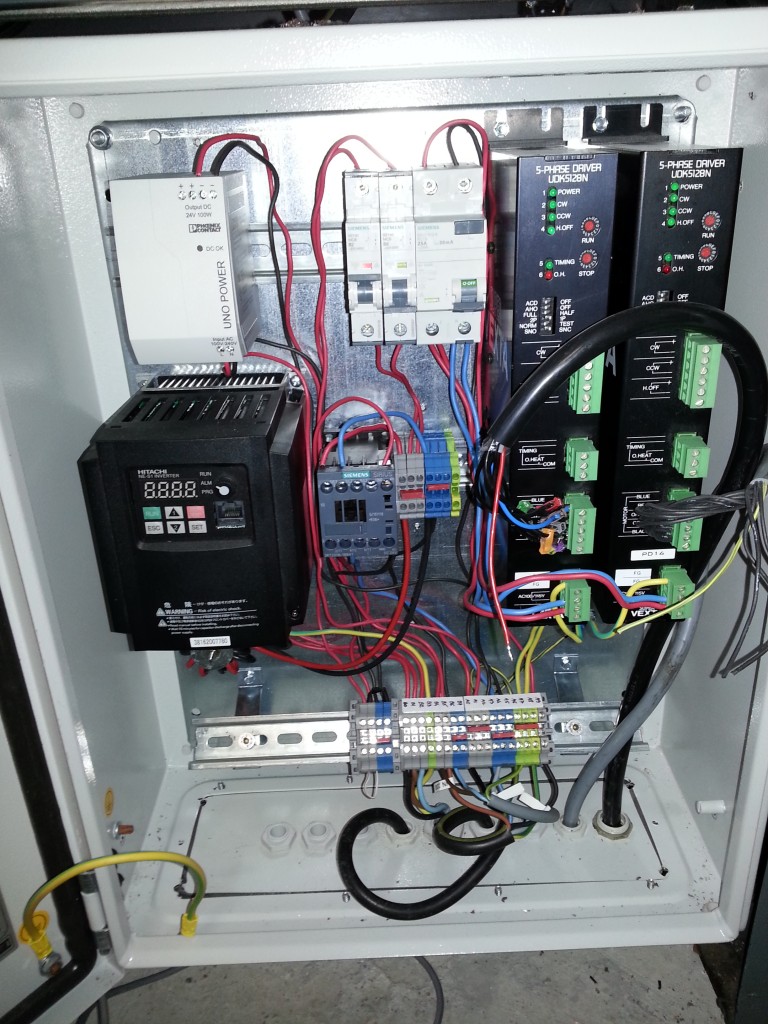

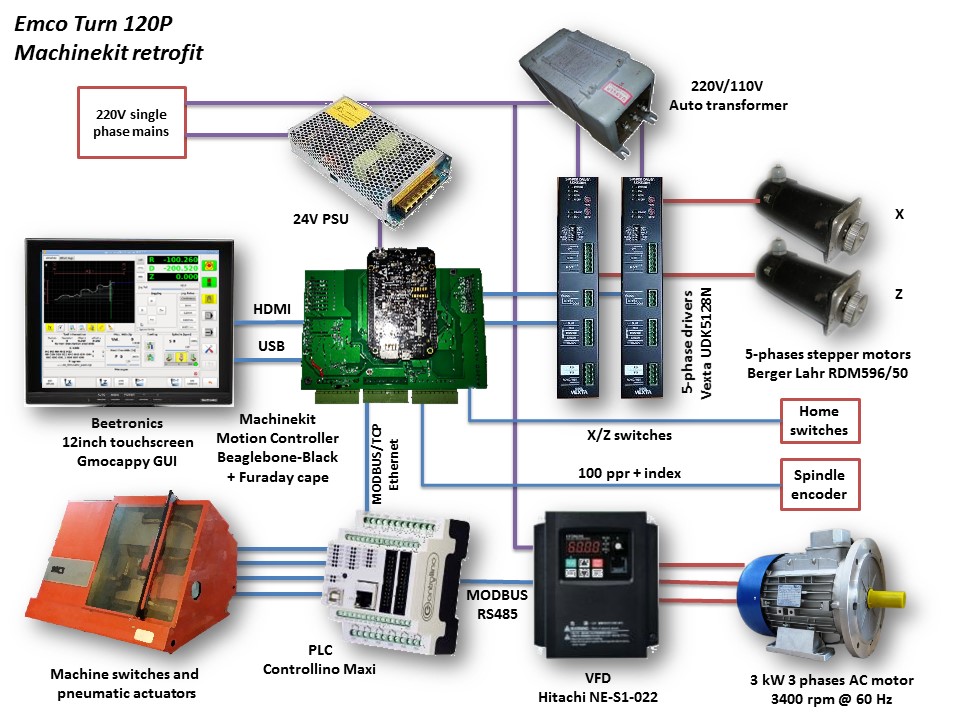

Emco Turn 120P retrofit electronics update

I have replaced the Probotix cape by a Furaday cape to get more I/O pins.

Here is the updated schematic diagram:

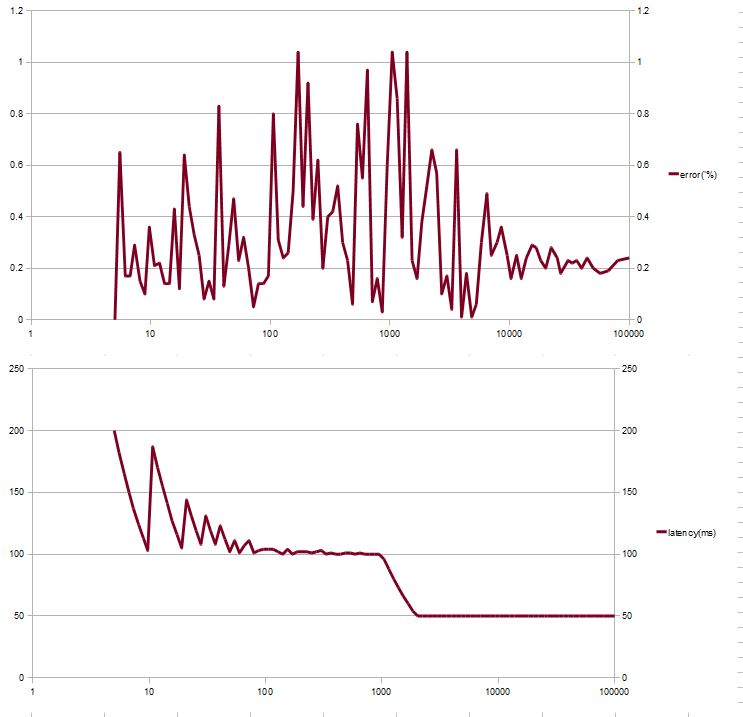

Adding velocity estimation in hal_pru_generic encoder

I needed this feature for my lathe control panel project. The goal is to drive the jog steps size by the rotation speed of the jog wheels.

The algorithm has been validated from 5 Hz to 100 kHz.

Maximum measurement error is 1%. See curves below.

The patch is available here: https://github.com/f1oat/machinekit

HAL configuration

loadusr -w ../setup.sh loadrt threads name1=servo-thread period1=1000000 loadrt hal_pru_generic prucode=$(HAL_RTMOD_DIR)/xenomai/pru_generic.bin pru=0 num_encoders=1 num_pwmgens=1 pru_period=2500 halname=hpg addf hpg.update servo-thread addf hpg.capture-position servo-thread setp hpg.encoder.00.chan.00.A-pin 7 #925 ENCxI setp hpg.encoder.00.chan.00.counter-mode 2 #Up Counter (counts rising edges on A, always counts up, B ignored) setp hpg.pwmgen.00.out.00.pin 921 #PWM1 setp hpg.pwmgen.00.out.00.enable 1 setp hpg.pwmgen.00.pwm_period 1000000 setp hpg.pwmgen.00.out.00.value 0.5 start loadusr -w sleep 1 loadusr -w python encoder_test.py

encoder_test.py

#!/usr/bin/python

import subprocess

import time

import os

def readpin(p):

r = subprocess.check_output('halcmd -s show pin ' + p + '|head -1',shell=True)

lst = r.split()

return lst[3]

def setpin(p, v):

subprocess.check_output('halcmd -s setp %s %d' % (p, v), shell=True)

freq = 5.0

prev_freq = 0.0

maxerror = 0

f = open('result.csv', 'w')

line = 'in(Hz), out(Hz), err(%), latency(ms)'

print line

f.write(line + '\n')

time.sleep(2)

while freq < 100e3:

period = int(1e9/freq/2500) * 2500 # because pru_period=2500

real_freq = 1e9/period

if (real_freq <> prev_freq):

prev_freq = real_freq

setpin('hpg.pwmgen.00.pwm_period', period)

time.sleep(0.2)

measured_freq = float(readpin('hpg.encoder.00.chan.00.velocity'))

latency = float(readpin('hpg.encoder.00.chan.00.latency')) * 1e-6

error = abs(real_freq / measured_freq - 1.0)

maxerror = max(maxerror, error)

line = "%8.1f, %8.1f, %4.2f, %3.0f" % (real_freq, measured_freq, error*100.0, latency)

print line

f.write(line + '\n')

freq = 1.1*freq

f.close()

print "Max error %.1f%s" % (maxerror*100.0, '%')

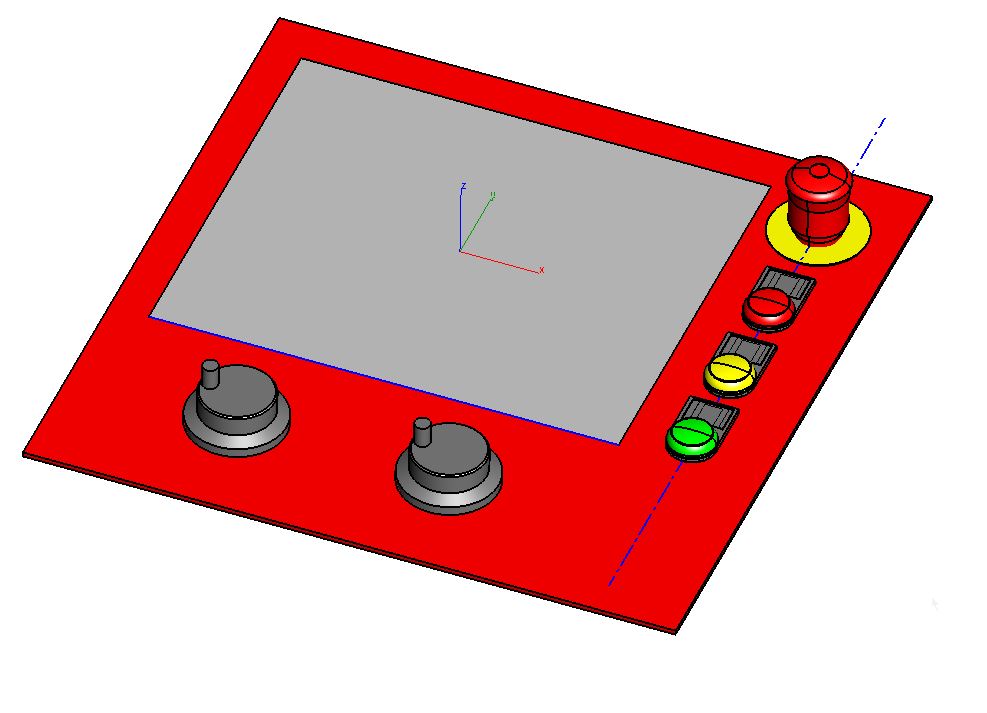

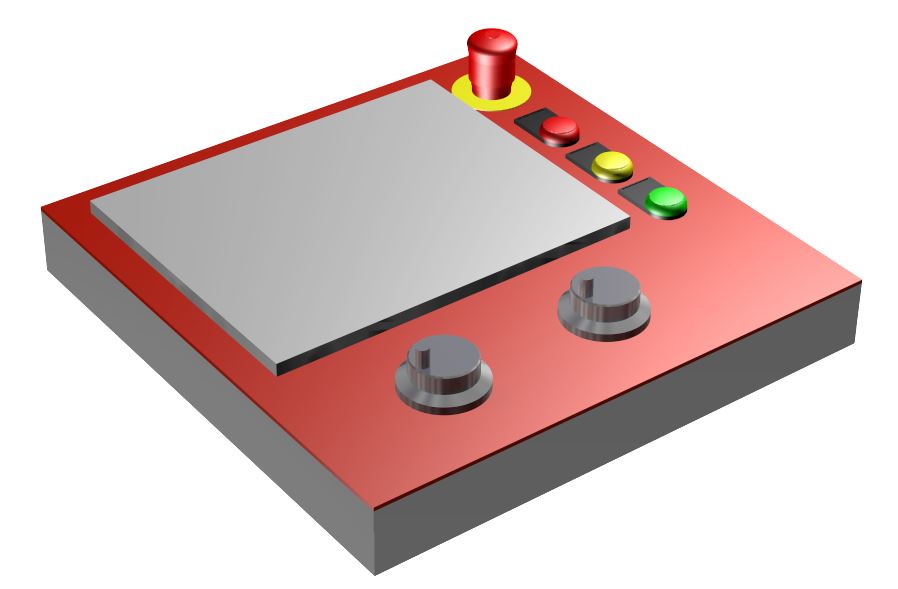

Emco Turn 120P Machinekit control panel

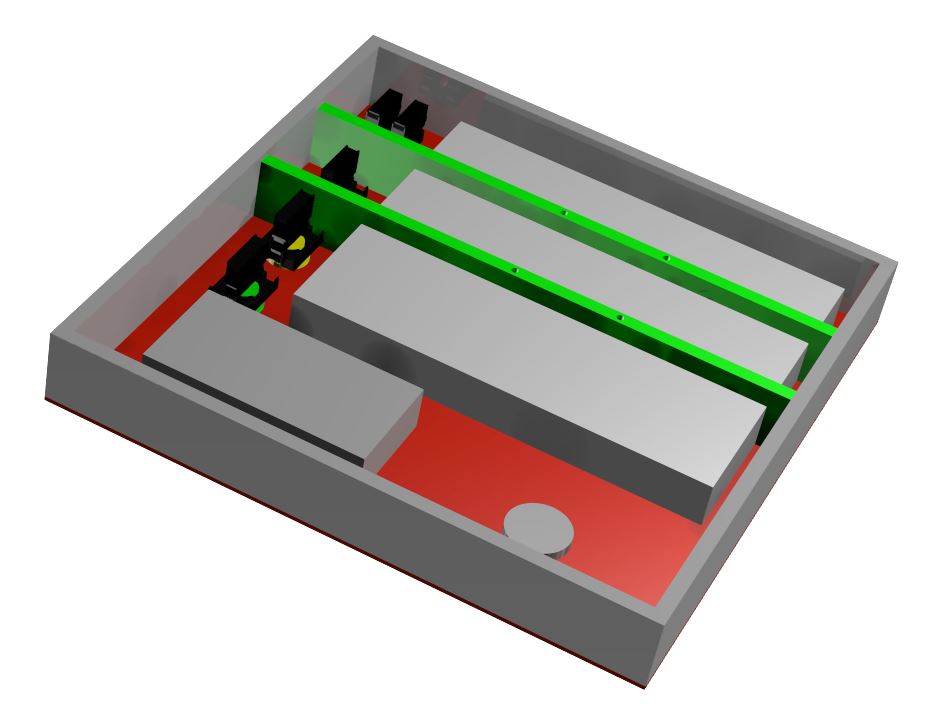

Brainstorming, CAD, CAM, simulation, wood, machining, gluing, sanding, HIPS … the control panel is almost ready!

The structure of the control panel is made of 5mm plywood. The red color is coming from a 1mm sheet of HIPS. Everything machined on my CNC-6040 router with 3.17mm carbide endmill.

The touchscreen is a Beetronics 12″ model. Connected through HDMI to the BeagleBone Black board. Easy configuration: there is native support for the touchscreen USB pointing device in the Machinekit Linux image!

Step by step manufacturing of the control panel.

First step was CAD design with ViaCAD software.

Some 3D rendering with ViaCAD.

High quality CG rendering and compositing with DAZ3D Carrara 8.5.On the real machine, I will add a frame to hang the panel above the sliding door area.

CAM done with BobCAD-CAM. Below a simulation to check everything before machining.![BobCAD-CAM - [Emco120 Control Panel V14 Cover]_2016-03-20_13-56-58](http://blog.f1oat.org/wp-content/uploads/2016/03/BobCAD-CAM-Emco120-Control-Panel-V14-Cover_2016-03-20_13-56-58-1024x600.jpg)

Plywood panel machined with 3.17mm carbide endmill. Some pockets to have 2mm thickness for industrial buttons fixture.

Gluing all parts together, and waiting 2 hours before removing clamps. Final result!

Final result!

MPG and lights will be managed by an Arduino UNO. Stay tuned …