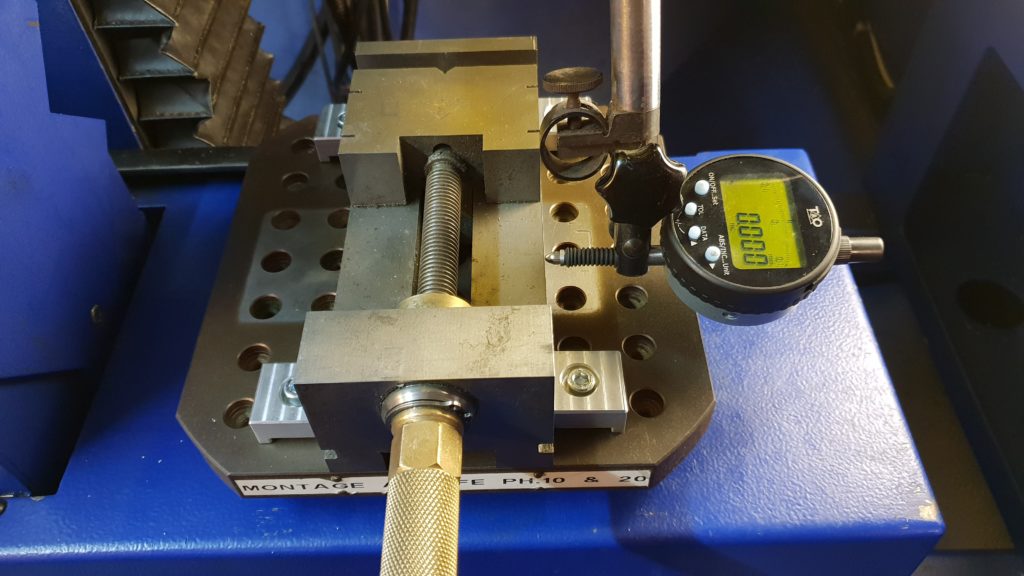

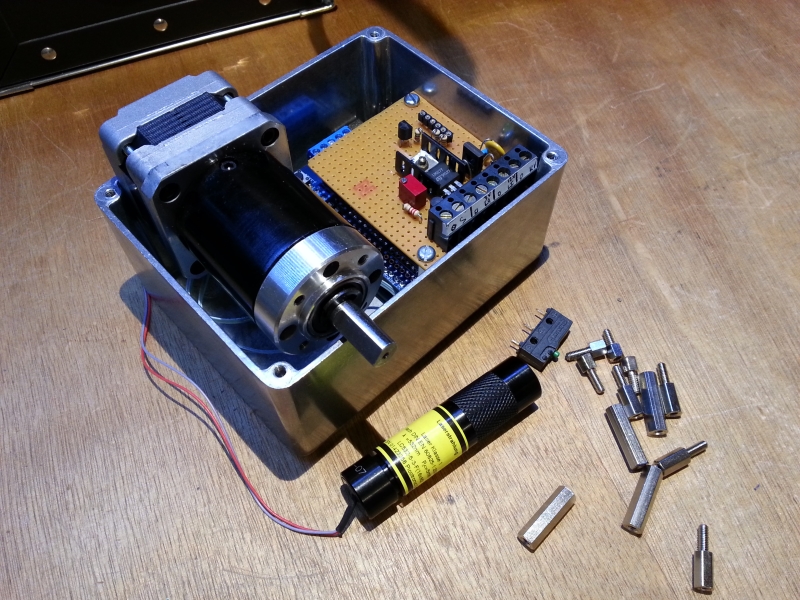

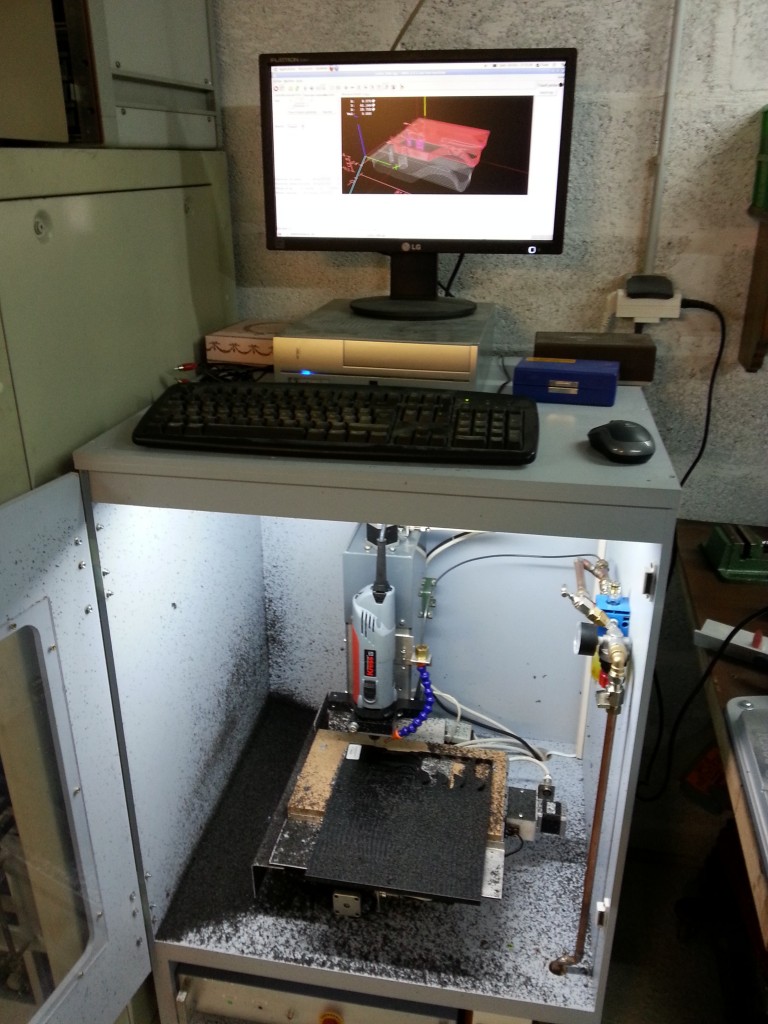

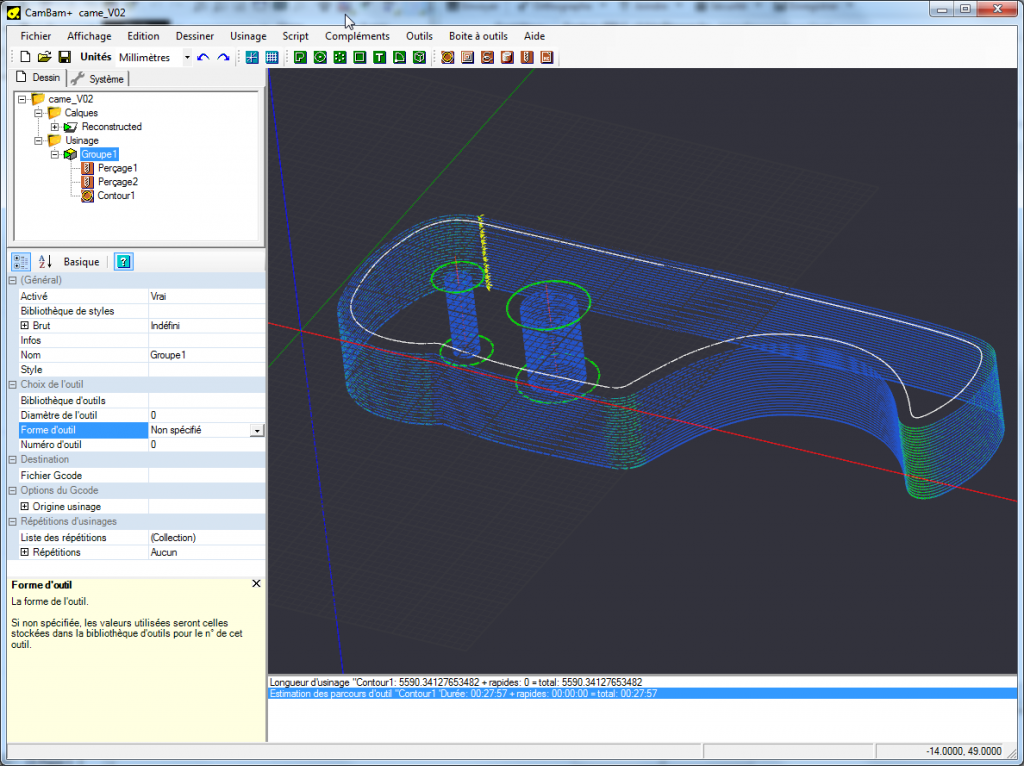

Time to machine some aluminum clamps for a nice vise.

To be used on the palet of my Intelys C3000.

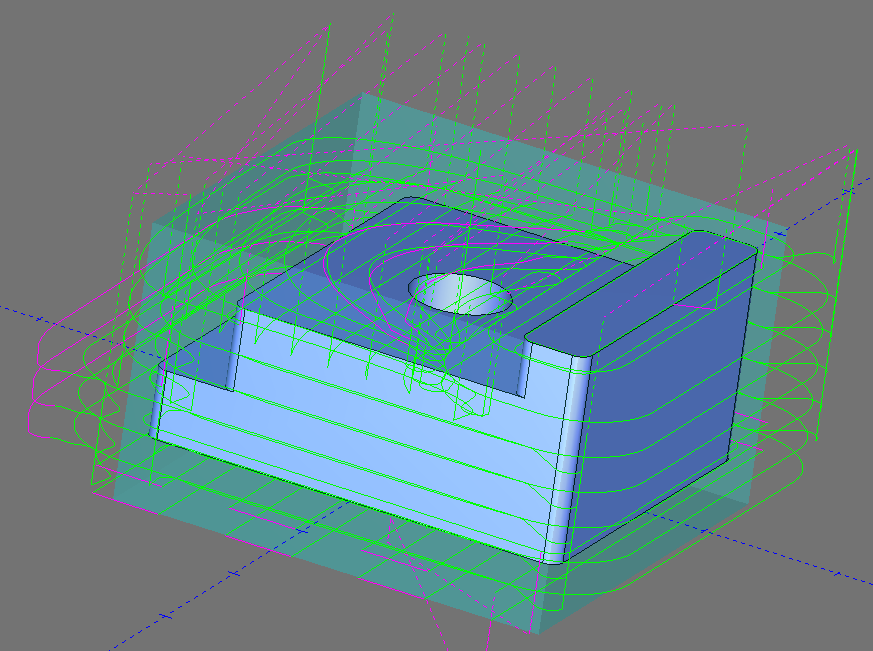

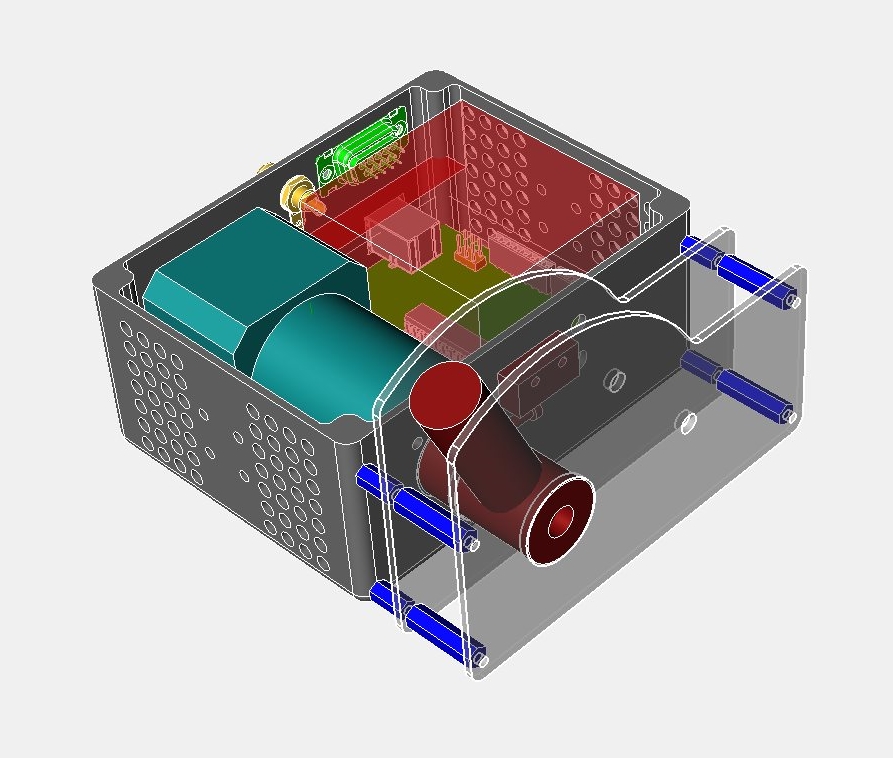

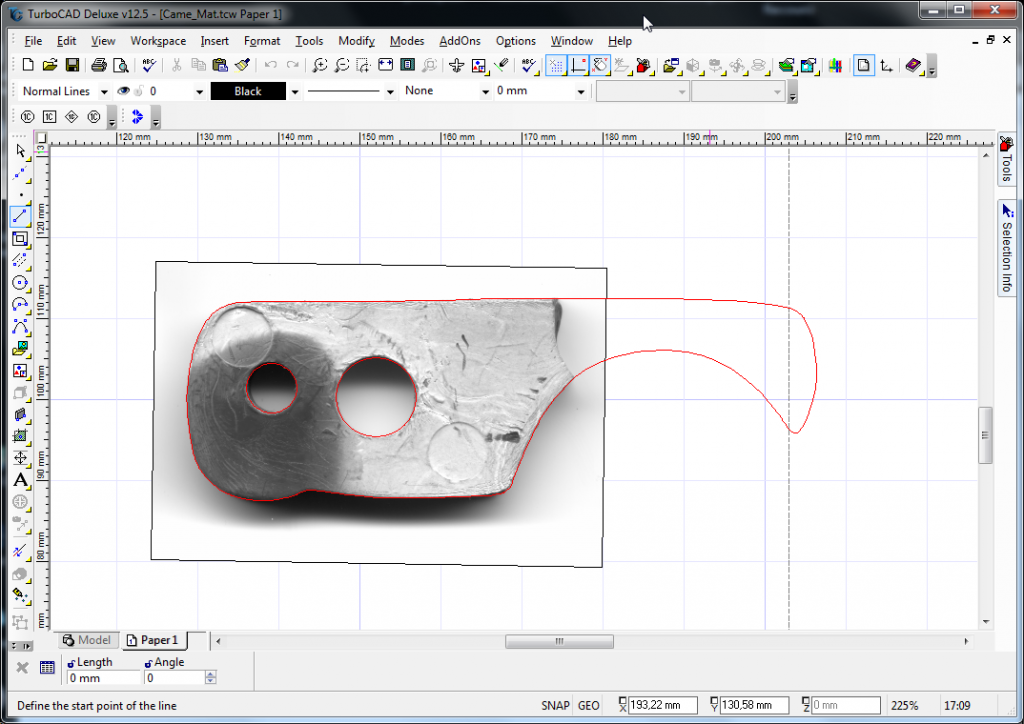

First time I am using 3D printing to check the part before wasting material and time with CNC milling: very useful, let me fix some design flaws before machining!